Products

GI (Free Galvanize) Cable Tray

The most widely used coating for cable tray is galvanizing. It is cost-effective, protects against a wide variety of environ mental chemicals, and is self-healing if an area becomes unprotected through cuts or scratches. Steel is coated with zinc through electrolysis by dipping steel into a bath of zinc salts. A combination of carbonates, hydroxides and zinc oxides forms a protective film to protect the zinc itself.Resistance to corrosion is directly related to the thickness of the coating and the harshness.

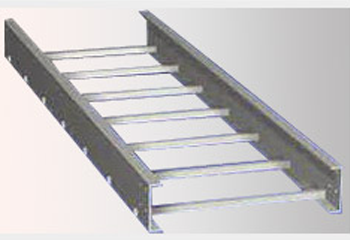

Hot Dip Ladder Cable Tray

After the steel cable tray has been manufactured and assembled, the entire tray is immersed in a bath of molten zinc, resulting in a coating of all surfaces, as well as all edges, holes and welds. Coating thickness is determined by the length of time each part is immersed in the bath and the speed of removal. Hot dip galvanizing after fabrication creates a much thicker coating than the pre-galvanized process, a minimum of 3.0 ounces per square foot of steel or 1.50 ounces per square foot.

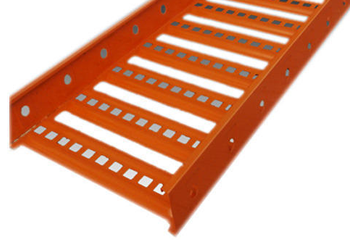

Power Coated Cable Tray

Our production of Powder Coated Cable Tray is finding demands in different industrial sectors. Thus, we have employed strict quality parameters to check for any defect in material acquisition. Our production team is well equipped to handle the short deadline set by the customers. The quality team works tirelessly to ensure that clients need not bother with usage. We have a sophisticated warehouse facility to ensure safe and secure temporary preservation of end product.